You may know Blue Gee from their GRP and Carbon boatbuilding and repair products. They recently launched a new two-part adhesive called Gee Pro Bond and I obtained a review sample to evaluate.

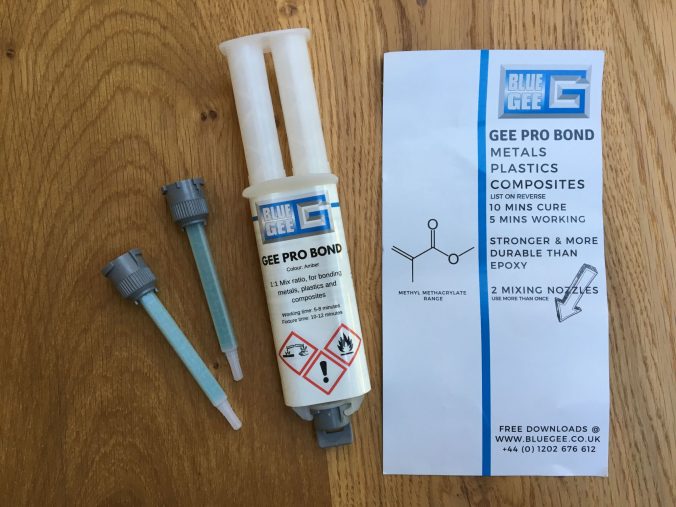

Initially this looks a lot like an epoxy, but it isn’t. It comes in a 25ml pack which is a double-barrelled syringe and two mixer nozzles. The bond and hardener are mixed with a 1:1 ratio so you can mix from the tube, but the mixer nozzle makes it a whole lot easier if you are bonding a larger area. You only get two nozzles, and they look well made so I expect supplying more would make the pack more expensive.

The best feature (apart from the bonding) is the cure time. It has a five-minute work time so you have to move fast, but it cures in 10 minutes. This makes it very useful when you need to get something fixed and can’t afford to hang around for the longer cure times of epoxy adhesives.

Most metals can be bonded without any pre-treatment. You can bond plastics, ABS, acrylics, vinyl, PVC, polycarbonates, composites, epoxy laminates, GRP polyester / vinyl ester and gelcoats. It is not suitable for polyolefins, thermoplastic polyesters, fluorocarbon plastics and other low surface energy plastics as they are generally not bondable with anything. It is also not good for wood unless the wood has already had an epoxy coating.

I have often thought that we don’t use specialist adhesives enough in boatbuilding and maintenance. One common challenge is fixing fittings to a GRP skin – either an internal moulding or the hull itself. With this adhesive you can bond a countersunk bolt head to the GRP surface leaving the thread sticking up looking like a stud, and simply bolt the fitting to the thread. I tested this idea with an extending arm to hold my iPad. I didn’t want to drill through the bulkhead so I simply bonded a bolt to the GRP. A single bolt was able to support the iPad, on an arm extended about 200mm is some choppy sea conditions where the strength of the bond was severely tested. It came through rock solid.

I also made up some test pieces for destruction testing. As expected, wood on wood and wood on GRP held, but without strength. It would probably be OK for cosmetic applications but not where strength is required. Much more impressive were the metal to GRP tests and plastic/GRP to GRP – these stood up to considerable force and the plastic to GRP bond never failed – the GRP itself delaminated before the bond broke.

In conclusion, this is a useful adhesive for specific, high strength quick cure applications.

Leave a Reply

You must be logged in to post a comment.